September 2025

- jameslawrence87

- Oct 4, 2025

- 2 min read

Early in the month, attention was split between 30075, 30076, and the eight-plank wagon. On the wagon, painting of the floor plank ends progressed, the tarpaulin support bar was nearly completed, and the vacuum hoses were fitted.

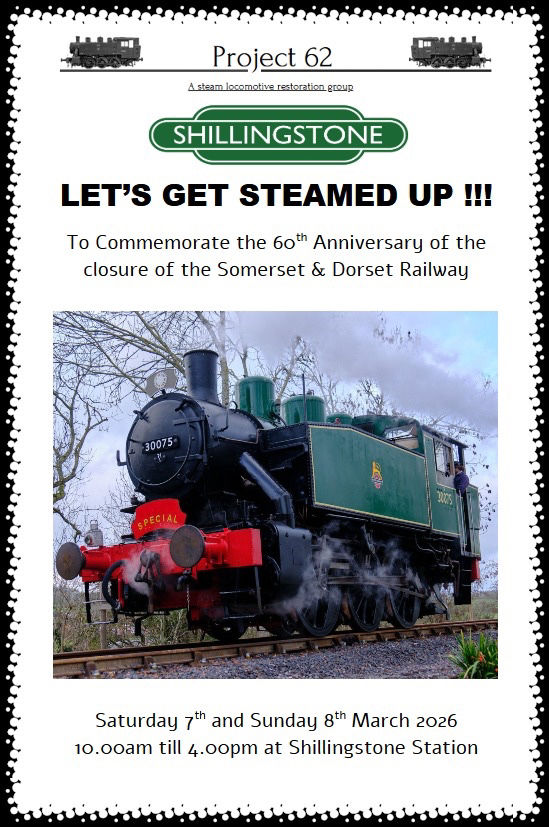

On 30075, repaired vacuum pipework was tested successfully using the railway’s diesel shunter, confirming the leaks were fixed. The manifold steam valve, re-brazed by Paul Antell, began refitting, and a Project 62 Committee meeting agreed to a further steam test on 18 September, with a warming fire the day before.

By 6 September, painting and fitting of the wagon floor planks had begun, and further work was completed on the tarpaulin support bar. On 30075, the refitted steam control valve was completed, several paint touch-ups were carried out, a general oil round was done, and preparations for the steam test began with coal and wood being gathered.

On 10 September, the tarpaulin bar fitting was completed and more floor planks were installed on the wagon. On 30075, additional wood was collected for the test, while 30076’s steam manifold was removed from the cab and placed on the workshop bench for overhaul.

By 17 September, the wagon’s floor timbers were close to completion, dimensions for a new tarpaulin were finalised, and a warming fire was lit in 30075’s firebox ahead of its test. Overhaul work continued on 30076’s manifold.

On 18 September, 30075 took part in the railway’s Extension Opening Celebrations, performing well apart from minor issues with the drain cocks and small vacuum ejector. This was a special invitation only event, to thank the Shillingstone volunteers for all their hard work restoring the railway. Project 62 hope to hold a similar event in the future, to thank all of our supporters for their fantastic work and financial support. Info to follow soon.

Later in the month, 30075’s drain cocks were removed and cleaned, the cylinders flushed, and joints on the vacuum pipes tightened ahead of pressure testing. Some priming was carried out on the steam pipe covers, and angle grinding on the smokebox door prepared it for welding. On the eight-plank wagon, only two floor planks remained to be fitted, and the new tarpaulin was ordered.

The next month will focus on completing the wagon’s overhaul, resolving minor issues on 30075. Please contact us if you are interested in hire of 30075.

Comments