May 2025

- jameslawrence87

- Jun 7, 2025

- 2 min read

Throughout the month, work progressed on both the eight-plank ex-ash wagon and locomotive 30075. On the wagon, fitting and adjustment of the door hinges took place, with new fixing holes drilled into both the hinge plates and the door framing. Surface preparation of the chassis continued, including the use of angle grinders to remove corrosion prior to priming. Timber panel sections were also treated, and a supporting angle bracket for one of the side doors was drilled and bolted in place. The vacuum through-pipe system was delivered and largely installed, including trial fitting and securing of brackets to carry the pipework beneath the wagon.

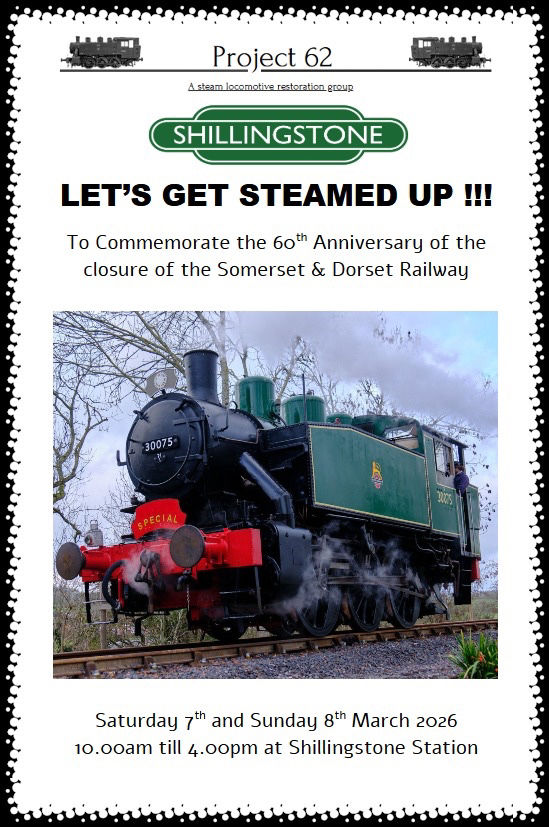

On 30075, mechanical fitting continued across multiple areas. The right-hand cylinder cover was bolted into place, and both front and rear drain cocks were reattached to the cylinders. The linkages for the rear set were installed and adjusted. The Gresham “Dreadnaught” vacuum ejector was mounted, and eight oil delivery pipes in copper were shaped and fixed to position, forming part of the mechanical lubrication system. The whistle isolating valve was removed, its joint remade, and then reinstalled. Following return from overhaul, the right-hand clack valve and the blower control valve were fitted and connected to the existing pipework. A survey of the water system identified two minor leaks at union joints, which were stripped, cleaned, and reassembled.

A steam test was undertaken on Wednesday 21 May, following the completion of these preparations. During initial pressurisation, a fault with the gasket on the left-hand clack valve caused a temporary halt while a replacement was fitted. Testing then resumed and pressure was taken up to 160 psi. Several steam leaks became evident at this stage, most notably at the joint between the steam dome and the boiler shell, and at the left-hand cylinder cover. Additional minor leaks were noted around ancillary pipework.

The dome cover was released and the copper sealing ring retrieved, cleaned, and sent to Paul Antell’s workshop for annealing. The dome cover itself was be lifted to allow full cleaning of the mating surfaces. A pressure gauge was removed for bench testing after signs of a slight weep under working conditions. Remaining issues are being addressed in preparation for a repeat steam test.

With this restore / test / learn approach to restoration of 30075, we are approaching our next steam test where we will establish if our repairs are sufficient. Our steam ticket of 10 years will start once our locomotive has been signed off by the boiler inspector - then 30075 is ready for the UK heritage railway circuit! Do contact us if you might be interested in hiring 30075 for your railway.

We are at Shillingstone station every Wednesday and some Saturday's.

Comments